Getting trained professionally for a job has always held sway in today’s world. That’s why we have universities and vocational colleges after all. This sway also seems to hold in the manufacturing industry.

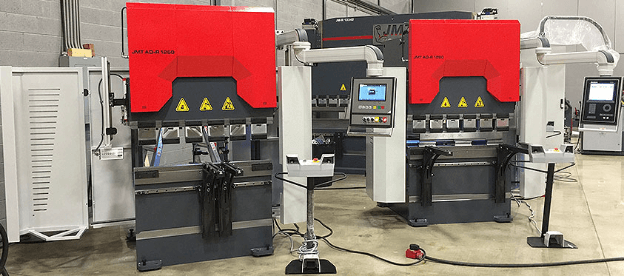

Most companies that make use of press brakes have press brake operators. The success of this part of the process sometimes is all down to the effectiveness of the press brake operators.

There are certain things these operators have to know about CNC press brakes. Having a good understanding of these things is imperative. Let’s take a long at some of them;

Maintenance

CNC press brakes are built to take a lot of intensity. The truth is that most press brakes can work around the clock every day for a very long time.

An operator will need to know the maintenance measures that need to be followed as well as when they need to be done. This will largely depend on the type of press brakes that are being used.

For example, if you are dealing with press brakes that use hydraulic, then a lot of emphases will be drawn towards a change of oil as well as removing debris from the machine. You might also need to change the filters as well as lubricate the part of the press brakes from time to time.

Tonnage Limits

It is also important to know the minimum and maximum weight that your press brakes can take. It is all too familiar that an operator that has not been trained messes with the tonnage limits of a press brake.

The key to finding the particular limit will be to measure the distance between the two sides. Then multiply the result by 60 percent. Once this has been done, divide the answer by the machine tonnage. That will give you the ideal weight limit.

Surpassing the limit of the machine can lead to damaged parts and in a worst-case scenario, severe damage to the machine.

Calculating the Bend (Inside Radius)

Calculating the bend of a CNC press brake is also very important. The truth is that metal can only be bent so far until it gives in and breaks.

The operator’s job, in this case, is to find out exactly when the metal is going to give in to the bend and how to use the spring back effectively.

While calculating this, it is important to note that all metals are not forged from the same material. This means that the level of pressure they can withstand will be different.

Final Thoughts

The first thing to do if you are an operator is to get yourself a good CNC press brake. Getting a good one will reduce the troubles that you might face even for a trained seasoned operator.

You’d also have to make sure you get it from a good manufacturer. Once this has been done, following these tips will surely lead any press brake operator to success.